MY ROLE

Product Designer

TIMELINE

May 24' - August 24'

TYPE

B2B SaaS & Consumer Portal

OVERVIEW

Protomold is an advanced digital manufacturing platform designed to streamline the process of procuring custom parts.

PROBLEM STATEMENT

How might we simplify the custom manufacturing process while considering time, cost and quality of production ?

BREAKING DOWN THE PROBLEM

User Pain Points

TIME - Delays

Finding reliable manufacturer requires extensive networking

Endless Back & Forth with Manual Follow ups

QUALITY - Lack of Feedback

Design Flaws due to manufacturability checks

Poor material choice with no structured process or precision

COST - Budget Overruns

Hidden cost and Cost escalation disrupt planning

Rework wastes time, money and materials

TRANSPARENCY - No Update

No Real Time Order Tracking or Feedback provided

No system for managing manufacturers

Understanding Users

" We have the capacity to produce parts but need a trusted partner to create high quality, precise molds efficiently. "

MNCs : Mold Manufacturing

Emerging Innovators & Startups

MNCs : Parts Production

VISION

Make Custom Manufacturing as seamless, fast and user friendly as ordering food from swiggy and zomato : Customize according to need and place order.

USER GOALS

Simplified Ordering Process

OBJECTIVE

Deliver a seamless User Experience

KEY RESULTS

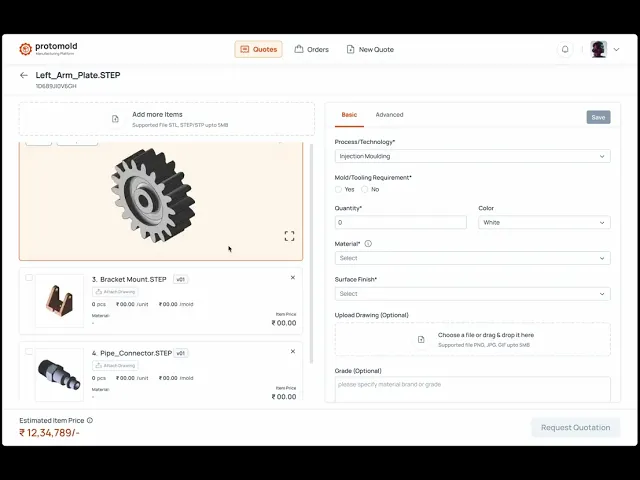

Design an Intuitive UI that allows users to complete Key Tasks (Quoting, Placing Order) in 4- 7 clicks

Reduce the avg. time to complete a Quote process by 50%

USER GOALS

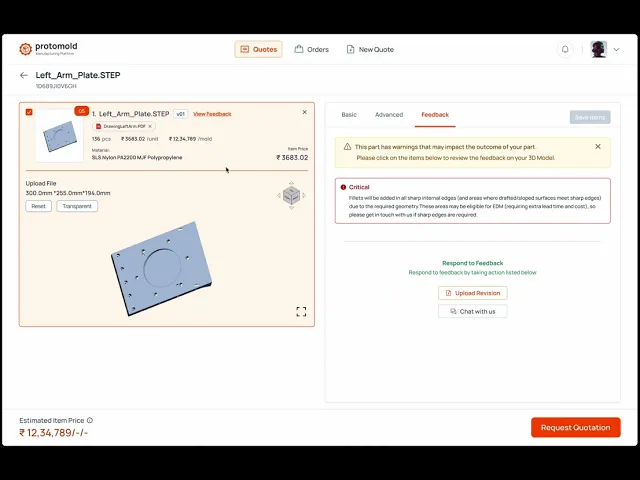

Accurate & Transparent Pricing with simplified DFM Feedback

OBJECTIVE

Leverage Automation

KEY RESULTS

Integrate AI driven Quoting System that

Reduces manual intervention by 50%

Delivers instant quotes with a response time of under 5 minutes

Implement a real-time DFM Feedback Mechanism that detects and flags design-related issues

USER GOALS

Clear Communication & Updates

OBJECTIVE

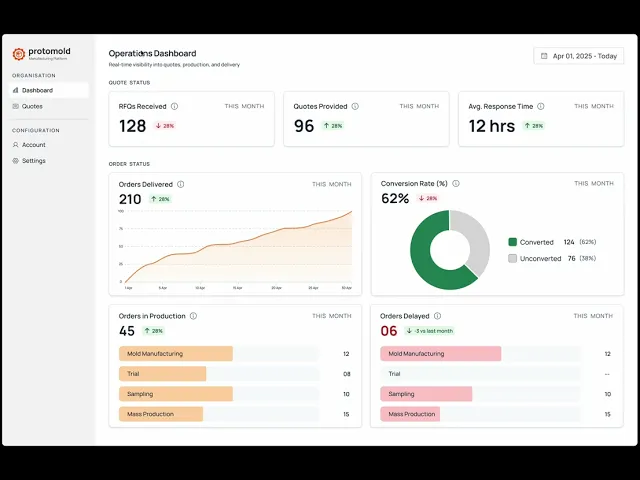

Enhance Transparency

KEY RESULTS

Launch real time order tracking with status update & alert for all orders

Build a robust support system that ensures timely assistance

USER GOALS

Quality Assurance

OBJECTIVE

Ensure Quality and Reliability

KEY RESULTS

Establish rigorous Quality assurance protocols with Quality Check Report with every Delivery to reduce rework

Achieve 95% order accuracy & on-time delivery for initial orders.

INSPIRED BY INDUSTRY LEADERS

CUSTOMER JOURNEY

SERVICE BLUEPRINT

FEATURE PRIORITISATION

Given the extensive backstory and the end-to-end scope of the product, this is a true 0 to 1 project—built from scratch to streamline and digitize a traditionally manual and fragmented manufacturing process.

As a result, we narrowed down our design scope to the following:

User Side – Quoting System

Admin Side – Dashboard, Quotes Tables & Part Review

User & Admin Feedback System

SOLUTION

KEY TAKEAWAYS

I learned how to bridge business needs, customer goals, and real-world operations — turning scattered workflows into a product that works for both sides.

I discovered service blueprint and how powerful it can be in turning a messy, disconnected process into something clear, structured, and full of insights.

The chaos in Indian manufacturing showed me how much room there is for smart systems — and how global players like Xometry, Fictiv & Protolabs are setting the benchmark.

I learned why it’s crucial to set clear goals for your product vision — and how measuring progress against those goals keeps the work focused, meaningful, and aligned with real outcomes.